Advantages of paper packaging

Advantages of paper packaging

Jan .09.2023

Among many packaging materials, paper packaging is more in line with contemporary green and low-carbon requirements. Its material characteristics also enable it to be used many times, and discarded with less impact on the environment, while having a high

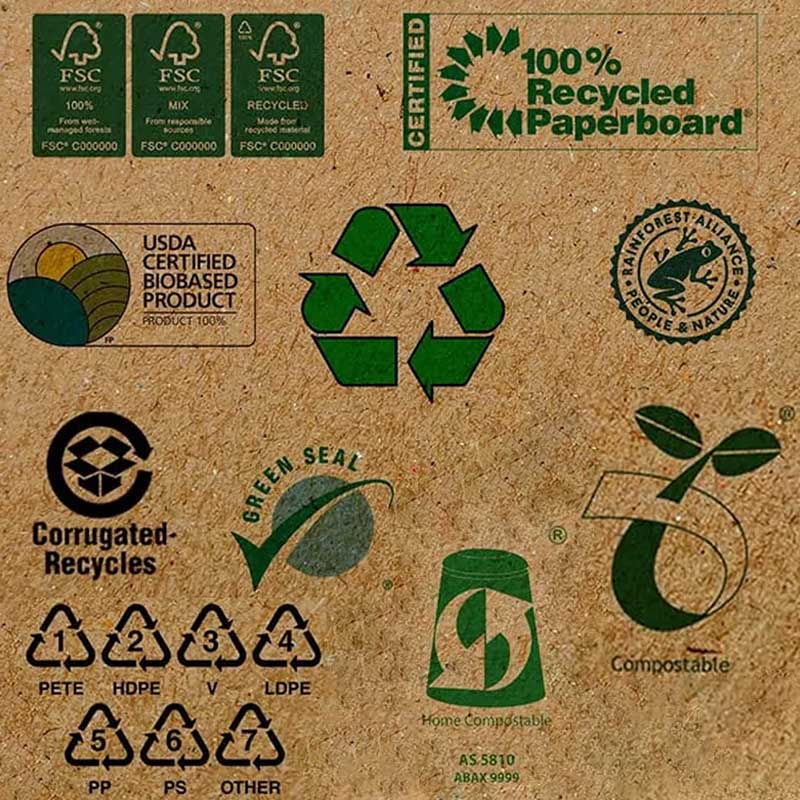

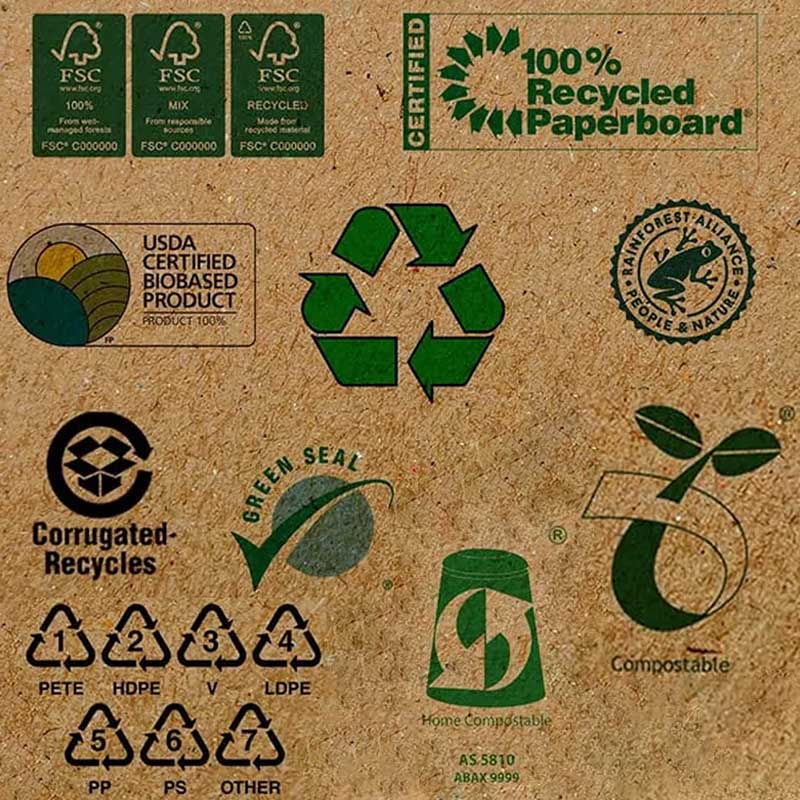

Get Clear About 22 Common Food Package Symbols Mean

Get Clear About 22 Common Food Package Symbols Mean

Dec .18.2022

Every country in the world has relative standards to the food packages' design, some symbols are must printed. They can help the consumers to clearly know your products and help safeguard both parties' legitimate rights and interests better. As the manufa

It's time to start preparing for Christmas

It's time to start preparing for Christmas

Nov .11.2022

Winter has come! It's time to start preparing for Christmas. Seasonal themed packaging is a great way to give your brand some extra relevance. Each year, a multitude of businesses invest in new packaging that speaks to the spirit of the season - to the po

Advantages of paper packaging

Advantages of paper packaging

Expert opinion | What should we do in the future to deal with the problem of flexible film recycling?

Expert opinion | What should we do in the future to deal with the problem of flexible film recycling?

Get Clear About 22 Common Food Package Symbols Mean

Get Clear About 22 Common Food Package Symbols Mean

It's time to start preparing for Christmas

It's time to start preparing for Christmas